Heat and cool Cycle Molding

About Heat and cool cycle molding

Heat and cool cycle molding involves repeated steam heating and water cooling of the mold through heating and cooling ducts installed near the inner surfaces of the mold. Rapid heating and cooling also realize practical mold cycling.

- ■ Characteristics

- 1.Inconspicuous weld lines (also eliminates flow marks and hazing)

- 2.Excellent application of textures

- 3.Realizes ultra-high gloss

Equipment

■ Molding

Molding Machine, under

200 t /

Molding Machine, under 850 t / Molding Machine, over 850 t

■ Particular facilities

Heat and

cool

Molding /RHCM Injection Molding / Gas Injection Molding / PIM Clean room PP Recycling Equipment / Pellet

Processor / Laser Cutter Robot / Produced Parts

Produced parts

< Air Conditioner >

< TV Parts >

< Washing machine >

< Washing machine >

< Automobile >

< Automobile >

< Automobile >

< Automobile >

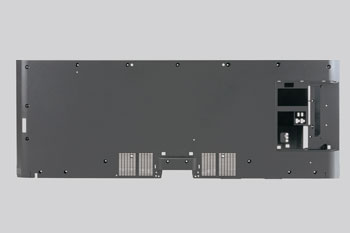

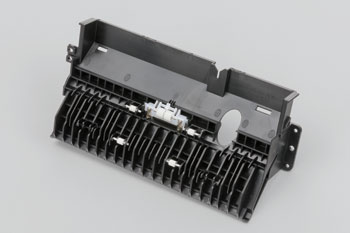

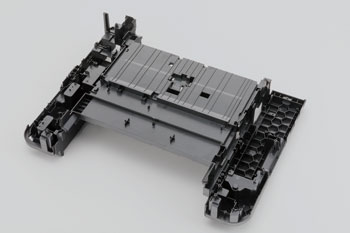

< Printer >

< Printer >

< Printer >

< Printer >

< Household-related goods >

< Medical equipment >

Finishing and Assembling

The rotary coating equipment has a rotary gun allowing it to handle a variety of coating methods. For example, we have added a function enabling the gun to slide sideways in addition to the traditional rotational function. The combination of these movements allows it to handle the coating of products with complex surfaces. Handles thick film coating, high quality primer coating, and thin film overglazing.

Reversible robot. Coats products while simultaneously removing products which have already been coated.

The drying oven allows operation in four patterns enabling it to flexibly handle a variety of tasks.

- 1. Double circulation operation.

- 2. Reverse operation.

- 3. Parallel operation.

- 4. Reverse parallel operation.

Used water discharged from the coating booth is collected by this machine where the water and paint are separated. The paint is discharged as waste, while the water is sent back to the coating booth to be reused.

Air from outside the plant is pumped into the building to keep the inside pressurized. This creates a flow of air from the inside to the outside whenever a door is opened, preventing unfiltered air, dust and other particles from entering the building.

The neutralizing room has an ion generator which neutralizes the static electricity of dust and other particles by discharging a shower of positive and negative ions.

Printing and Assembling

■ Printing

Silk printing / Pad printing

■ Assembling

Plasma television assembling / Air conditioner assembling /

Refrigerator assembling